Views: 0 Author: Guangdong Rolansini Home Furnishing Technology Co., Ltd. Publish Time: 2025-06-20 Origin: https://www.rolansini-windows.com/

We all know that heat-insulating and heat-preserving aluminum doors and windows can alleviate the temperature changes inside the room. But what role and significance does the air tightness of aluminum doors and windows play in cooling? Next, we will carefully explain what the benefits of air tightness are and how to improve the air tightness of doors and windows.

1.What is the air tightness of doors and windows?

The ability to prevent air infiltration.

Perhaps you are unfamiliar with the concept of a building's air tightness. Air tightness is an indicator term used to measure whether the enclosure structure is sealed tightly and whether there is any air leakage. The air tightness of a building can be understood as the ability of exterior doors and windows to prevent air infiltration when they are normally closed.

The air tightness requirements for doors and windows in the AS2047 standard are to ensure that doors and windows effectively prevent air infiltration when closed, thereby improving energy efficiency, acoustic performance, and preventing external contaminants (such as dust and noise) from entering the interior. The following are the specific requirements and testing methods for air tightness in AS2047:

1.1 Air tightness test requirements

Test pressure difference:

The air tightness test is evaluated through two pressure difference levels: 75Pa/ 150Pa

The criteria for judgment:

The maximum allowable air leakage varies depending on the type of door or window and the usage scenario (such as whether it is an air-conditioned room):

For air-conditioned rooms: The requirements are stricter, with the maximum allowable leakage being 1/5 of that for non-air-conditioned rooms, and both positive and negative pressure tests are required.

For non-air-conditioned rooms: Only positive pressure test is needed.

1.2 Specific Air Tightness Performance Indicators

The following are the air tightness performance indicators stipulated in AS2047 (units: L/(s·m²) or m³/(h·m²)):

| Building type or window type | Pressure direction | 75Pa maximum penetration | 150Pa maximum penetration |

| Air-conditioned room | Positive pressure | 1.0 L/(s·m²) | 1.6 L/(s·m²) |

| Non-air-conditioned room | Positive pressure | 5.0 L/(s·m²) | 8.0 L/(s·m²) |

| glass louver window | Positive pressure | 20.0 L/(s·m²) | not applicable |

| Adjustable glass louver window (residential and commercial) | Positive pressure | 20.0 L/(s·m²) | 32.0 L/(s·m²) |

1.3 Test Methods

Air tightness testing is conducted in accordance with AS 4420.4 standard, with the following specific steps:

Positive pressure test:

Apply positive pressures of 75Pa and 150Pa to the doors and windows and measure the air leakage.

For non-air-conditioned rooms, only positive pressure testing is required, while for air-conditioned rooms, both positive and negative pressure tests are necessary.

Negative pressure test:

Only for air-conditioned rooms, apply negative pressures of 75Pa and 150Pa to ensure bidirectional sealing.

1.4 Special Requirements

Influences of Materials and Design:

The airtightness index may be adjusted based on the material of the doors and windows (such as aluminium alloy, wood, UPVC) and the application scenarios (residential, commercial). Refer to AS/NZS 4420.1: 2016, 7 (Wind Load Standards) and AS/NZS 4420.1: 2016, 3 (Deflection Test).

1.5 Test Objectives

Energy Efficiency: Reduce the energy consumption of air conditioning/heating systems and lower the operational costs of buildings.

Comfort: Prevent external noise and dust from entering, and enhance the indoor environmental quality.

Structural Protection: Avoid moisture accumulation and material aging caused by air infiltration.

Air tightness refers to the ability of an exterior (door) window to prevent air infiltration when it is in a normal closed state. The air tightness performance of exterior windows is directly related to the heat loss caused by cold air infiltration. Air tightness is divided into 8 grades. The higher the grade, the smaller the heat loss and the better the air tightness. Good air tightness is conducive to energy conservation and environmental protection.

Good air tightness of buildings makes a very important contribution to improving energy efficiency. It involves many fields of building physics and not only affects the insulation, moisture-proofing, sound insulation and fire protection of buildings, but is also closely related to the shielding of harmful substances, and ensures the normal operation of effective ventilation systems, optimizes air quality, and creates conditions for improving energy efficiency and comfort.

Good air tightness is not formed naturally and needs to be considered in all construction stages. The air tightness layer of the entire building should be clearly defined in the design stage. It should be a continuous and uninterrupted closed circle that covers all heated areas. Attention should also be paid to the reasonable arrangement of the construction sequence. The red line in the following figure indicates the air tightness layer at the door and window openings.

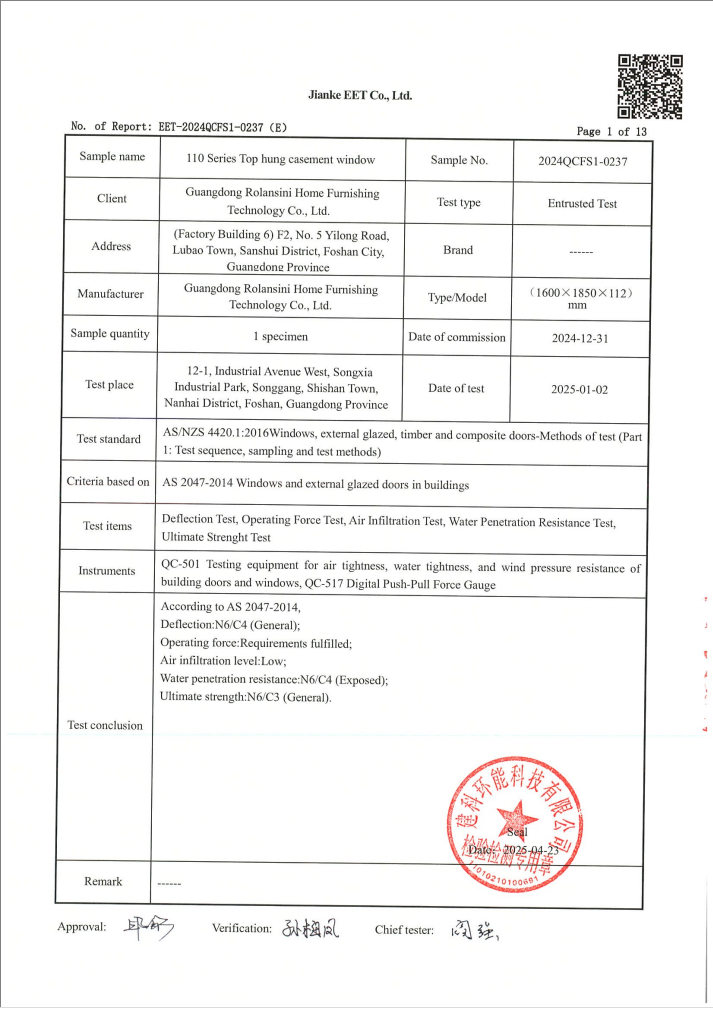

Our aluminum alloy doors and windows products have passed the AS2047 product testing. The Air Infiltration Test result is low.

2. Benefits of airtightness in aluminum doors and windows

Insulation in winter and heat insulation in summer.

In regions where insulation is necessary, the temperature difference between indoors and outdoors is significant in winter. Cold air seeping into the room can lead to heat loss and increase the energy consumption for heating. Improving the airtightness of doors and windows helps reduce heat loss and lower overall energy consumption, which is of great significance for energy conservation in buildings.

In summer, after turning on the air conditioner for cooling, the temperature difference inside and outside the room is also large. Air leakage can bring a large proportion of the total load to non-central air conditioners. Enhancing airtightness can effectively reduce energy loss from air conditioners and make them more energy-efficient. Of course, during the transitional season, it is advisable to lower the screen window and open the fan blades. High airtightness is not conducive to ventilation. Using natural ventilation becomes more energy-efficient and comfortable.

3. Factors Affecting Air Tightness

Sealing of Profile Installation.

3.1 Door and Window Profiles

The structure and material of door and window aluminum profiles have a significant impact on the airtightness of doors and windows. Wooden doors and windows have the poorest airtightness, followed by aluminum alloy doors and windows, injection-molded aluminum doors and windows, and advanced system-integrated thermal break aluminum doors and windows, which perform the best in terms of airtightness.

Whether the airtightness of doors and windows is up to standard is directly related to the compressive strength of the material. Materials that are prone to deformation or rust and oxidation may cause gaps between the frame and the glass, resulting in poor sealing performance and subsequent problems such as air leakage, water leakage, and dust entry.

When purchasing doors and windows, it is important to choose high-quality aluminum profiles first to avoid buying low-quality thermal break aluminum doors and windows. It is recommended to choose well-known brands of thermal break aluminum doors and windows to ensure their quality and stability. Rolansini doors and windows system are recommended, which use custom ultra-high precision thermal break aluminum profiles to guarantee their quality and stability.

3.2 Door and Window Installation

Door and window installation is divided into three parts: the frame part, the hinge part of the casement swing door and window, and the sliding rail part of the sliding door and window. The quality of installation is also an important factor determining the airtightness of the door and window. For the frame part, after vertical positioning, it is fixed with foam and iron strips. Then, the gaps need to be filled with cement. After the cement has solidified, it is best to seal it again with a small amount of sealant to further enhance the airtightness.

For the hinge part, after installation, further detailed adjustments are needed to make the fan blade fit the frame more closely, ensuring the overall sealing of the door and window, which can effectively improve the airtightness of the door and window.

3.3 Door and Window Sealing Strips

The most common problem with sealing strips is that they do not fit well with the sealing rings and show signs of aging, cracking, hardening or even powdering. Rolansini selects high-grade EPDM sealing strips with anti-aging properties, which can reduce the frequency of replacing sealing strips and also ensure their sealing performance. In addition, dry agents can be sprayed at the sealing points of doors and windows to keep the sealing rings dry and prevent corrosion from water accumulation.