Views: 0 Author: Guangdong Rolansini Home Furnishing Technology Co., Ltd. Publish Time: 2025-06-09 Origin: https://www.rolansini-windows.com/

With the upcoming winter rainy season in Sydney and Melbourne, persistent rainfall brings inconveniences to daily life and work. Due to the high humidity, aluminum alloy door and window systems are prone to water seepage, water accumulation in the internal structure, dampness in the wall openings, condensation, etc.

Watertight performance refers to the ability of closed windows and doors to resist rainwater leakage under simultaneous wind and rain forces. If the aluminum casement window’s watertight performance is poor, rainwater can penetrate indoors via wind-driven pressure during storms. Rolansini Window and Door System has long provided comprehensive solutions to address leakage issues.

1. What Is Watertight Performance?

The ability of windows and doors to withstand rainwater.

Before explaining watertight performance, let’s clarify a common misconception.

Many believe rainwater falls vertically, akin to staying dry under an umbrella outdoors, assuming roofs alone prevent indoor exposure.

This is fundamentally incorrect. In nature, rain and wind always coexist. The AS2047 standard tests watertight performance under simulated “wind-rain combined” conditions (details follow).

So, how does “wind-rain combined” occur in real life?

Beyond natural storms, two scenarios critically impact aluminum window and door systems:

Typhoons: Extreme winds and heavy rains create intense pressure differentials.

High-rise effects: Wind speed increases with height. A gentle breeze at ground level becomes a 20th-floor gale, turning light rain into horizontal deluges.

Thus, evaluating watertight performance requires testing under “wind-rain combined” conditions via AS 4420.5 Water Penetration Testing.

2. What Is AS 4420.5 Water Penetration Testing?

2.1 Testing Principle

Validates water resistance of aluminum window and door systems under simultaneous wind pressure and rainfall. Tests apply simulated wind loads and continuous water spray to assess leakage prevention.

2.2 Testing Methods

2.2.1 Water Spray & Pressure Simulation

Spray Phase: 5-minute zero-pressure-difference water spray (simulates rainfall).

Pressure Phase: 15-minute combined water spray + designed pressure (150Pa–450Pa, per product grade).

Pass Criteria: No leakage = pass; leakage = fail.

2.2.2 Dynamic Wind Pressure & Rain Impact

Equipment alternates positive/negative wind pressures while simulating storm-level rainfall.

2.3 Testing Standards

AS 4420.5 Water Penetration Test

AS 2047 mandates AS 4420.5 compliance for aluminum casement windows, with parameters adjusted per application (residential/commercial), material (aluminum/wood), and climate (e.g., cyclone zones).

Pressure Classifications (AS 2047):

Minimum: 150Pa (N1/N2) for standard aluminum window and door systems.

High Demand: 300Pa–450Pa (N5/N6) for cyclone-prone regions (Zones C/D).

3. Rolansini Aluminum Window and Door Systems Pass AS2047 Certification!

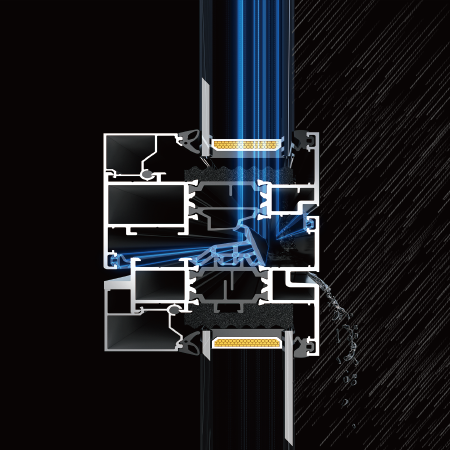

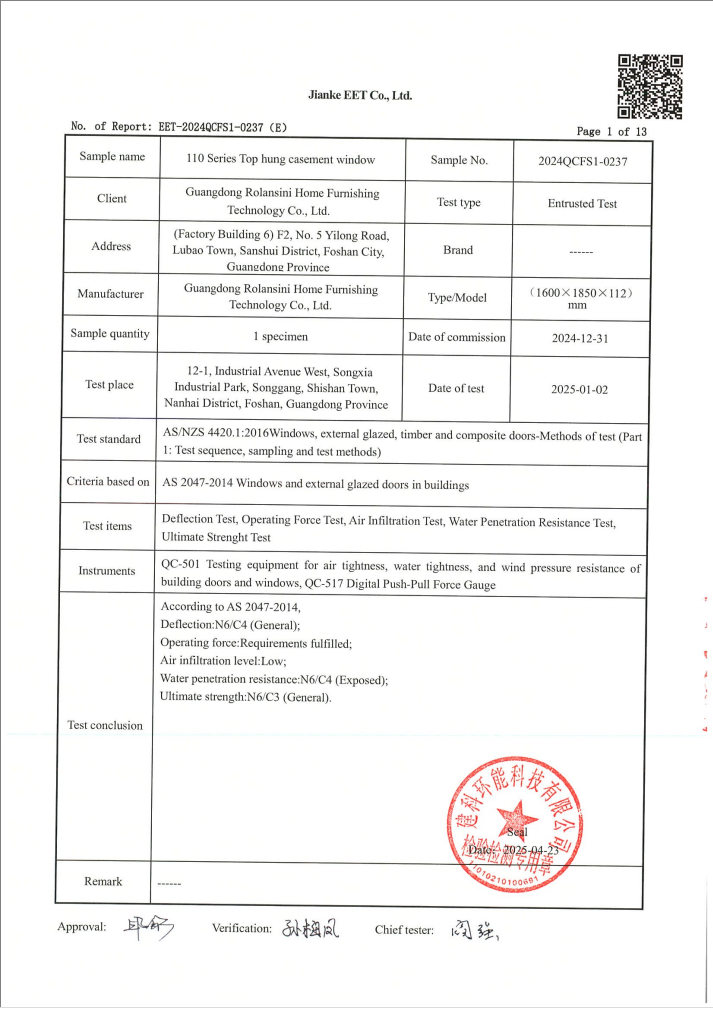

One of the Main Product: 110 Series Thermal Break Aluminum Double Glazed Glass Casement Window

Test Conclusion (AS 2047-2014):

Deflection: N6/C4 (General)

Operating Force: Requirements fulfilled

Air Infiltration Level: Low

Water Tightness: N6/C4 (Exposed)

Ultimate Strength: N6/C3 (General)

Our AS2047-Compliant Aluminum Window and Door Systems:

✅ Completed Australian projects

✅ Ongoing collaborations in Australia

Local Support

Our Sydney office provides end-to-end services: Production (domestic),Customs clearance & export,Ocean freight logistics,On-site installation,After-sales maintenance.

Conclusion

AS 2047’s watertight tests replicate extreme “wind-rain combined” conditions to rigorously validate aluminum casement window performance. This methodology aligns with Australia/New Zealand’s storm-prone climate while setting clear technical benchmarks for aluminum window and door manufacturing.

Moving forward, Rolansini remains committed to its mission: “Crafting Better Windows and Doors, Safeguarding More Homes and Families.” Driven by user needs, technological innovation, and global vision, we collaborate worldwide to advance sustainable development in the construction industry.

content is empty!